|

|

About Griffiths Evans Family Tree

FAMILY ROOTS OF PETER ALBERT GRIFFITHS

I grew up in Cwmavon (or Cwmafan) in the Afan valley in South Wales. My father’s family had always lived there with records going back to 1800 whilst my mother’s family had lived in Tonmawr since the early 1900’s and before that in Glyncorrwg, (although her father was born and raised in Brecon). At home we had quite good contacts with immediate family, particularly on my mother's side, but we knew very little let alone meet more distant relatives. As we had no car or telephone one had to rely on public transport to visit anyone. This was limited in the Afan valley, making it almost impossible, for example, to travel from Cwmavon to Glyncorrwg and those members of the family that had moved further away were 'lost'.

The lives of family members were intimately linked with the changes that occurred throughout the valley in period 1810 to 1950 when it was transformed for a peaceful agricultural setting to a nightmare of industrial development. Hundreds of mines were dug into the sides of mountains and dozens of pits were sunk into the valley floor to meet the demand for coal. Iron, copper and tin plate industries with their associated furnaces belching out fumes, sprung up to meet the needs of the industrial revolution. The was a huge demand for manpower resulting in people from all over the country coming to the area to seek employment. Living conditions were poor but many of the houses hastily built to accommodate the workers survived into the 1960’s and were still lived in whilst I was at home.

During my childhood a few coal mines were still operating in the upper reaches of the valley but most of them had closed, as had other the other industries, leaving behind their legacies of slag heaps coal tips and derelict buildings. Not a pretty site for the most part. Despite the huge economic and social changes this period brought to the valley and the devasting impact it had on the environment I don't recall being taught or indeed any mention of it being made in either school I attended. My awareness of the previous century may have been high as it was all around me, but my knowledge was almost non existent. Similarly my parents never really talked about it at home. It was probably too recent for them, with painful memories of hardship and chaos. The post war period presented an opportunity for a new start when they could move on and leave the past behind. They encouraged me and my brother to look to the future and through success in education they saw the prospect of us having life styles that they had been denied.

As a consequence much of the content of this document is new to me. I had never heard of many of the family members before this research and I never understood the extent and complexity of the industrialization of the valley and the impact it had on the family. This is an attempt to put the record straight – better late than never

INDUSTRIAL HISTORY OF CWMAVON, TONMAWR AND GLYNCORRWG

The river Afan is one of the many rivers that drain the South Wales mountains. Its source is in the small village of Blaengwynfi and along its 12 mile north east to south west course to the sea at Aberavon it is joined by tributaries such as the Pelenna and Corrwg. Tonmawr situated on the Pelenna and Glyncorrwg on the Corrwg feature prominently in the history of the ‘Evans’ families whilst the ‘Griffiths’ lived all their lives in Cwmavon.

In the 18th century, before the industrial revolution the valley was largely rural with scattered farms and cottages. Oak trees covered the hillsides , whilst on the valley floor crops were grown and cattle grazed. In the upper valley much of the farmland was bog or marsh with sheep grazing on the uplands although, even then, farmers were known to dig coal from seams found on the surface.

The rocks of the Afan valley are the coal measures laid down 300 million years ago. Over 40 coal seams exist in South Wales, separated by shales, muds and sandstones whilst clay and bands of iron ore also present. The quality of coal increases from east to west with bitumen (good for smelting) found in the east, steam coal (the best for steam engines) in the central region and anthracite (the highest in heat generation) in the west. The coal seams are basin shaped so that in the narrow, steep sided parts of the valley coal could be extracted from drift mines or levels cut into the hillsides whilst on the valley floor deep mines had to be sunk to reach the seams.

Above Pontrhydyfen the upper valley is steep sided and is scattered with mining communities whilst at the lower end, centred on Cwmavon, the valley is wider allowing space for the development of iron and tinplate industries as well as the production of copper.

CWMAVON

Cwmavon lies a couple of miles due north of the old town of Aberavon, which itself is now subsumed into the industrial town of Port Talbot. It is situated in probably the widest part of the Afan Valley being about a mile at its widest and 3 miles in length. The village church of St Michaels dates back to the 12th century, the old ecclesial Welsh name for the parish being Llanfihangel Ynys Afan, whilst public records of the 19th century refer to the parish as Michaelson Super Avon.

In 1801 the population was 201 but this grew rapidly in the next 50 years to over 6000 with the advent of the coal, copper, iron and tinplate industries. People arrived from all over the UK and Ireland in search of work including great, great grandparents, Richard and Sarah Adams who arrived in the late 1830’s from Devon. It is estimated that at its peak 25% of the population was made up of families from England and about 30% of the workforce in tin plate production were female. However the direct ‘Griffiths’ line can be traced back to Griffith Griffiths born in 1804 in Cwmavon and the subsequent 4 generations of the family have members who have lived in the village many of whom having worked all their lives in local industry.

The industrialization of Cwmavon commenced in 1811 when SF Lettsom took a 99 year lease on 1000 acres of land for £1 an acre from the Earl of Jersey. Planning to build a tin works he first commenced mining for coal to feed the furnaces. The first level called Wern marked the beginning of Cwmavon works. Over the next 80 years as the works expanded the demand for coal grew and grew. A number of levels were dug into the Foel mountain, the largest being at Cwm Mawr up on the Bwlch behind Woodland Row, as well as on the other side of the valley near Cilcarn farm. Three pits were also sunk into the valley floor; Ynys David, Meadow and Engine. The demand for coal in the works steadily increased such that by 1874 the company owned collieries in Oakwood, Pontrhydyfen and Bryn and had built major tramways to carry the coal to the coke ovens. In 1879 disaster struck the Meadow Pit when the rope broke during descent of the cage, killing 6 men.

Lettsom’s initial phase of extracting coal and iron ore from the Foel mountain in 1812 was followed in 1819 when he started to build the first blast furnace. However by this time he was in financial difficulty and he sold the business to two Cornishmen - John Vigurs and Leonard Smith in 1820. Vigurs and Smith already had tinworks in Ynys y Gerwyn near Aberdulais and transferred these actvities to Cwmavon. The works were completed in 1825 and in 1834 they added a chemical works.

Several factors made Cwmavon suitable for iron and tinplate production .Firstly the raw materials for the furnaces were available locally or could be obtained from docks only a couple of miles away and secondly, flat level land alongside a river provided space for the large industrial units and water power for the operation of bellows to provide air draughts to the various furnaces as well as the running of the rolling mills. The first stage in production of tin plate involved the production of pig iron through smelting in a blast furnace. The second stage was the conversion of pig iron into a malleable form in a puddling furnace and the production of wrought iron rods in a forge. These malleable iron rods were then rolled into thin sheets in a rolling mill before finally being coated with tin.

Early maps of the village show the development of the works in the centre of the village with housing for the workers on its periphery. The iron works were situated near the river on the site of the present day rugby ground whilst the tin works and the chemical works were located below Tabernacle Methodist chapel. Alongside the tin works were the brickworks and near the chemical works were located furnaces, coke ovens and lime kilns. Nobody had more than a few yards to go to work. Names of streets reflected their locality – Miners and Collier Rows were close to the original coal levels, Furnace Row was behind the furnaces whilst Meadow street was near the Meadow Pit. There was a ‘necrotic’ middle to the site brought about the removal of limestone to act as a flux and the deposit of the slag from the furnaces locally known as ‘Tips Gwyn’ (white tips). Alongside these tips there was a large pond – Brickworks pond –created by the removal of clays to produce the brick linings of the furnaces and to build housing for the workers.

The partnership of Vigurs and Smith came to an end in 1835 following which Vigurs continued alone as Vigurs & Co. In 1835 he stated to build the copper works with labour brought in from Cornwall and housed in Cornish Row, located alongside the works. Cornwall in the 19th century was the world’s largest producer of copper ore. The close proximity of the South Wales ports and the availability of coal for the furnaces led to a large number of copper smelting plants being developed in South Wales. They were particularly prevalent in the Swansea area as were smelting plants for other non ferrous metals such as zinc, lead, silver, gold and arsenic and form the basis of Swansea’s commercial wealth.

Smelting is the term given to the extraction of pure metal from ores found in the ground. Depending on the chemical form of the ore, smelting is one or two step process. Ores composed of carbonates or sulphideshave to be converted to an oxide through the direct action of heat. This generates large quantities of carbon dioxide or sulphur dioxide. Following this the copper oxide form can reduced to metallic copper by carbon monoxide a second furnace. Originally charcoal was used as the source of carbon monoxide but as production increased in the 19th century there was insufficient wood and coke was used instead. Coke is made from certain coals in a coking oven and such coals were found in the seams in the Cwmavon area .Limestone was again added to the process to serve as a catalyst and to chemically bind unwanted impurities to form a slag..The first consignment of pure copper was made in 1838 in the same year as Vigurs left Cwmavon for his home in Cornwall.

In 1840 the Cwmavon works were sold to the English Copper Company a subsidiary of the Governor and Company of Copper Mines in England. In 1848 the works were again in financial difficulty and was taken over by the Bank of England, the new title being the Governor and Company of the Bank of England with an accountant, John Biddulphs in charge. This was a difficult and austere period in the village but new workers continued to arrive swelling the population to over 6000. Biddulph was forced to leave the district in 1852 and the industry recovered such that in the 1860’s there were 5 blast furnaces in operation and together with Oakwood there were 42 puddling furnaces and 5 rolling mills. In 1884 the works were sold to the Rio Tinto Company who finally stopped copper smelting in 1899, transferring the business to Taibach.

As Cwmavon works developed so did the need for engineering support and in 1847 the Cwmavon Engineering Depot was built with extensive workshops on land adjacent to the present Depot Road in the village. The capacity and manufacturing ability within the Depot is reflected by the fact that it produced the largest rail in the world (62feet 5inches) for the Crystal Palace Exhibition in 1851.

In the period 1877 - 1899 the iron works had closed but in its place a new steel making plant had been built on the site of the chemical works and a second tin works is shown on the map near to Zion chapel on the road to Aberavon. As steel making became more common in the early 20th century a new steel making plants opened in Port Talbot in 1902 and Margam in 1915. This resulted in the final closure of most of Cwmavon works except for the new tin works which continued in some capacity until 1947.

With the closure of the works most coal mining in the are also ceased but the Oakwood colliery in Pontrhydyfen continued until 1927 (in 1924 it had a workforce of 450 men) producing household, manufacturing and steam coal and in Bryn the Bryn Navigation Collieries Co Ltd sank a new pit in 1894 for the production of household and manufacturing coal. At its peak it employed nearly 700 men and produced 96,000 tons per year. It closed in 1964.

One of the lasting legacies of the local industry was the Stack y Foel, a chimney 13 metres high built on the top of the Foel Mountain linked by a culvert of approximately 300metres, to the copper smelting works in the valley below. Built by the chief engineer of the time, Richard Bunton, it carried the smoke and fumes (it took 18 tons of coal to produce one of copper) away from the works to the health benefit of the workers, but unfortunately to the detriment of the surrounding environment, preventing anything growing on the mountainside for the next century, An early picture of the village depicting a pastoral scene in the foreground clearly shows the culvert in place up the Foel mountain in the background.

The chimney stood until 1940 when it was demolished as it had become a marker for German bombers in the 2nd World War. In its time it was regarded as one of the wonders of Glamorgan and one of the highest chimneys in the world.

Today there is little evidence of the village’s industrial past as the land once occupied by the tin and copper works now accommodate new housing and the village takes on the role of a desirable suburb of Port Talbot.

TONMAWR

Tonmawr was originally a small rural community on the banks of the Pelenna river that flowed via Evail Fach to join the Afan at Ponrhydyfen. Supporting the local farming community there were grist mills producing flour from corn as well as a fulling mill producing cloth from raw wool.. Much of the local land was owned by estates such as the Gnoll, Eaglebush, Earl of Jersey and Houghton who leased farms to local people.

In 1801 there were only 7 families with a population total of 72 living in 12 houses. This had grown by 1861 to 259 people living in 28 houses. The main development was Fforchdwm Row which was built to house the influx of new workers associated with the first coal level opened in the area in 1832 at Fforchdwm. This is the earliest industrialised housing development in the upper Afan Valley. Conditions were very basic, water for example being available from a spring 20 yards away, but the houses continued to be lived in until 1956 when they were eventually vacated.

Coal production continued in Tonmawr for the next 130 years, until the Garth Colliery finally closed in 1964. The first pit to be sunk was the North End followed by the Llantwit Merthyr, Garth (1893) and Whitworth (1910). The North End closed in 1931 and the Llantwit Merthyr in 1926 whilst the Whitworth was compelled to close after only 1 year of operation due to financial and drainage problems. In addition there were a number of levels dug into the mountainside, the most notable, for family reasons, being Craig Ddu. The mine was first listed in 1922 as being owned by the Graig (or Craig) Ddu Colliery Company , Port Talbot, a company set up by 2 mining engineers, Percy and Frederick Jacobs. Company records show a nominal capital of £3000 consisting of 3000 shares each of £1 A summary of its manpower and key personnel is given in the South Wales Coal Annuals (Editors AP Barnett & TJ Beynon) and shows that in 1924, 31 men were employed (27 underground and 4 on the surface) and this grew to a peak in 1930/31 when 51 men were employed and an ouput of 5000 tons of Household and Manufacturing coal. During this time the Colliery manager is given as A Evans. However in 1932 the number of miners fell to 23 and in 1933 the colliery became unprofitable and a receiver was appointed in March. In a letter to the Companies Registration Office in London, dated 23rd December 1933, official notice was given that the company had ceased trading and the colliery had been abandoned.

The transport of the coal from the area however was difficult due to the remoteness of the village. The first attempt was a tramway constructed in 1840 by Robert Parsons and Charles Strange, to connect with the Neath canal at Aberdulais. However the route proved uneconomic and it was forced to close in 1860. The second initiative in 1861, the South Wales Mineral Railway (SWMR) built by Isamabard Brunel connected Tonmawr to Briton Ferry docks. The Gyfylchi Tunnel, 1124 yards long was then constructed to allow the railway to enter the Afan valley. The SWMR and the Gyfylchi tunnel have strong family connections as the railway which transported coal from Craig Ddu Colliery, run by members of the Evans family and the tunnel for being the route home to Tonmawr for my mother when she worked at Dyffryn and Cynon stations. Apparently she walked at night in the pitch black with a torch from the eastern end of the tunnel towards a pin point of light at the western end, over half a mile away, where her father was waiting to meet her.

Tonmawr achieved international notoriety following the release of the film ‘the night of the Iguana’ in 1964. In response to the diatribe “ I am going to have you blacklisted in every travel agent in America, Africa, Tasmania and Beuchualand” , Richard Burton’s reply of “and what about Tonmawr” sent researchers in a spin to discover the village’s whereabouts. Richard was born in Pontrhydyfen and my mother used to babysit for him. Today Tonmawr is still home to Evans family members as well as to an excellent rugby club.

GLYNCORRWG

In the early 1800’s Glyncorrwg, like the rest of the Afan valley, was a community of cottages and scattered farms. Situated in the northern most branch of the Afan valley on the river Corrwg, it is the only community in the area identified on early maps and the local church of St John the Baptist has a history with origins as far back as the 5th and 6th centuries. It was not until 1863 did change begin with the opening of the first mine and the arrival of the SWM railway. In 1861 the population was 330 and this suddenly doubled in the next few years with the building of 65 new houses to accommodate the influx of new mine workers. By 1900 the village had reached a stable population of over 3000 which supported two ‘hotels’, a Co-operative store, drapers shop and at least two chapels

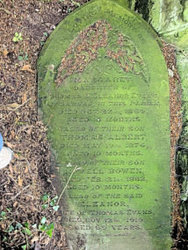

Amongst the new workers were great great grandparents William and Ann Evans from Pembrokeshire who arrived with their family in Glyncorrwg in the late 1860’s and great grand father John Davies from Aberavon who came in 1872. Over the next couple of decades the extended family had grown to about 20 people all living in close proximity in Brick Row. Although living all their adult lives in Tonmawr grandparents Albert and Elvira Evans are buried, together with Elvira’s mother and daughter, in the churchyard in Glyncorrwg.

Coal production in Glyncorrwg increased rapidly from 1863 onwards. In 1874 the North Rhondda Colliery Co. opened 2 drift mines which continued production until 1960.The first pits were sunk in 1904 when the Glyncorrwg Colliery Ltd sunk North and South pits, 417 & 403 yards deep respectively. These were the last to close in 1970. In 1954 a serious explosion occurred in the mine when 24 men were burned. In 1912 the Ynyscorrwg mine shaft was dug. This was a single shaft as the mine connected underground to the Scattern colliery at Blaengwynfi.which had opened in 1890. Both these pits closed in the 1920’s with the loss of 1000 jobs. The last pit to be sunk in the area was in 1919 at Nantewlwaeth, midway between Glyncorrwg and Cymmer. At 714 yards this was the deepest in the area. It eventually closed in 1948.

The decline in the fortunes of the South Wales coal industry started post World War 1 when the Royal Navy and the railways started to develop oil fueled engines. However the real demise was economic as in the period 1920-1940 the area had the lowest productivity, highest costs and lowest profits of all coal producing areas in the UK due to the over expansion during the late 19th century and failure to invest in mechanization by the owners.

Forty years on after the final pit closure little remains of the village’s industrial past. After a period of high unemployment it is trying to generate income through attracting visitors to newly constructed fishing ponds covering 6 acres as well as developing routes for walkers and cyclists coming to the Afan Forest park.

RAILWAYS IN THE AFAN VALLEY

Railways were an integral part of the development of the South Wales coalfield. The coal had to be transported to where it was needed and so mines had to be linked with industries lower down the valleys and to the ports for use further afield. There were large profits to be made and this provided the necessary incentive for the huge investment required to overcome the significant construction problems brought about by the difficult terrain. This saw the building of many viaducts and tunnels the longest of which was 2 miles long. During one period the upper Afan valley alone had no less than 3 independent railway companies operating in the area but no main road.

Although their primary role was industrial, railways brought about a certain integration of the valley by allowing for the first time easy movement of people. Stations were constructed in many of the small villages enabling people to visit coastal towns on market days for shopping or fair days for enjoyment as well as of course the seaside. In later years the railway also became the way in which most children from the Afan valley who had passed the Scholarship Examination were able to attend the grammar schools in Port Talbot as the Education Authority issued free passes and the train timetable fitted with that of the school’s.

The first attempt to transport coal from the mines was the Glyncorrwg railway which opened in 1842. Built by Robert Parsons and Charles Strange (and known locally as Parson’s Folly) it connected Blaencregan via Tonmawr and Tonna with the Neath Canal at Aberdulais,a total distance of 7.5 miles. It was originally intended to go as far as Glyncorrwg but finances ran out. Parsons had to pay way leaves to the land owners of 4/11 a ton but only received 4/9 a ton for the coal at Aberdulais and so ran at a loss.

The closure of Parsons folly was followed by new investment and the construction of the South Wales Mineral Railway by Isamabard Kingdom Brunel, linking Briton Ferry to Glyncorrwg via Tonmawr and a new tunnel,1124 yards long at Gyfylchi. The railway opened as far as Tonmawr in 1861 and then proceeded into the Afan valley via Gyfylchi to link Cynonville, Duffryn, Nant-y-Bar, Abercregan, Cymmer and Glyncorrwg in 1863, a total distance of 17 miles. It continued until 1910 when the section from Efail Fach to Briton Ferry was dismantled after which all traffic went through to Port Talbot. In 1925 the line to Glyncorrwg was closed and in 1947 a landslip blocked the western portal of Gyfylchi tunnel bringing about the closure of the whole line

Increased coal production and the associated increased profits led to further investment in the railway network. In the upper Afan valley a tunnel was constructed in 1877 to link Cymmer and Caerau allowing access to the Llynfi and Ogmore railway and Cardiff docks. In 1885 following pressure and financing from Swansea merchants work commenced on the Rhondda and Swansea Bay Railway The proposal involved running the railway from Swansea docks along Jersey Marine, crossing the Neath river in Briton Ferry, through the Sandfields to Port Talbot where it crossed the main road at Bethany Square to enter the Afan valley. It then proceeded to Cwmavon, Pontrhydyfen, Argoes, Cynonville, Duffryn, Cymmer Afanand and on to Blaengwynfi via a severn arch bridge and tunnel with curve. Its final section included a second tunnel 3443 yards long to Treorchy in the Rhondda. The construction of tunnels at the top of the valley allowed the railway to have long inclines thus overcoming some of the earlier design problems which required steep inclines at the start of the valley. The scheme was completed in 1890 under guidance of chief engineer Mr SW Yockney. By this time the Great Western Railway company had a controlling share in the RSB and by the end of the century owned it outright. The line continued to operate until 1964 when it was eventually axed by Dr Beeching.

In 1894, the Port Talbot Railway and Docks Company (PTR) was formed to directly link the port to the various competitive railways, particularly the South Wales Mineral Railway and the Rhondda and Swansea Bay Railway. In 1898 following the construction of a new viaduct at Pontrhydyfen and a section of line to Efail Fach, the SWMR and the RSB were linked allowing coal from Tonmawr to reach Port Talbot. The line eventually closed in 1947.

FAMILY ANCESTORS

Research into my ancestors has led to the production of comprehensive family trees with associated details and supporting documents which can be accessed through http://trees.ancestry.co.uk/tree/40299572/recent. This will give acces to media such as original census data and birth, marriage and death certifcate details.I have not repeated this detail in this document but have tried to provide a summary as well as a commentary on family affairs. I have taken as a reference point my great grand parents as they are the common source of all my second cousins i.e. my immediate family. These were:

Isaac Griffiths married to Caroline Adams;

Sophia Jones who never married;

Thomas Evans married to Eleanor Bowen;

John Davies married to Ann Evans |

LOADING! Please wait ...

Getting Around

There are several ways to browse the family tree. The Tree View graphically shows the relationship of selected person to their kin. The Family View shows the person you have selected in the center, with his/her photo on the left and notes on the right. Above are the father and mother and below are the children. The Ancestor Chart shows the person you have selected in the left, with the photograph above and children below. On the right are the parents, grandparents and great-grandparents. The Descendant Chart shows the person you have selected in the left, with the photograph and parents below. On the right are the children, grandchildren and great-grandchildren. Do you know who your second cousins are? Try the Kinship Relationships Tool. Your site can generate various Reports for each name in your family tree. You can select a name from the list on the top-right menu bar.

In addition to the charts and reports you have Photo Albums, the Events list and the Relationships tool. Family photographs are organized in the Photo Index. Each Album's photographs are accompanied by a caption. To enlarge a photograph just click on it. Keep up with the family birthdays and anniversaries in the Events list. Birthdays and Anniversaries of living persons are listed by month. Want to know how you are related to anybody ? Check out the Relationships tool. |

|

|